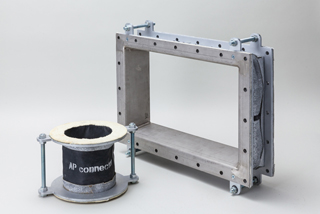

AP Connector is a non-metallic expansion joint used for the expansion part of bellows employing cloth and resin materials.

It combines the elasticity of nonmetal with a free range of materials to produce a variety of results, and can insulate duct piping against displacement, vibration, and/or stress.

AAMNo.

AP Connector is a non-metallic expansion joint used for the expansion part of bellows employing cloth and resin materials.

It combines the elasticity of nonmetal with a free range of materials to produce a variety of results, and can insulate duct piping against displacement, vibration, and/or stress.